01 What is EDI?

The full English name of EDI is electrode ionization, which translates to electric demineralization, also known as electric deionization technology, or packed bed electrodialysis.

Electrodeion technology combines ion exchange and electrodialysis. It is a desalting technology developed on the basis of electrodialysis, and it is a water treatment technology that has been widely used and achieved good results after ion exchange resin.

The electrodialysis technology is used for continuous desalting, and the ion exchange technology is used to achieve the effect of deep desalting.

It not only improves the defect of decreasing current efficiency when treating low concentration solution in electrodialysis process, enhances ion transfer, but also makes ion exchanger can be regenerated, avoids the use of regenerant, reduces the secondary pollution generated during the use of acid and base regenerant, and realizes continuous deion operation.

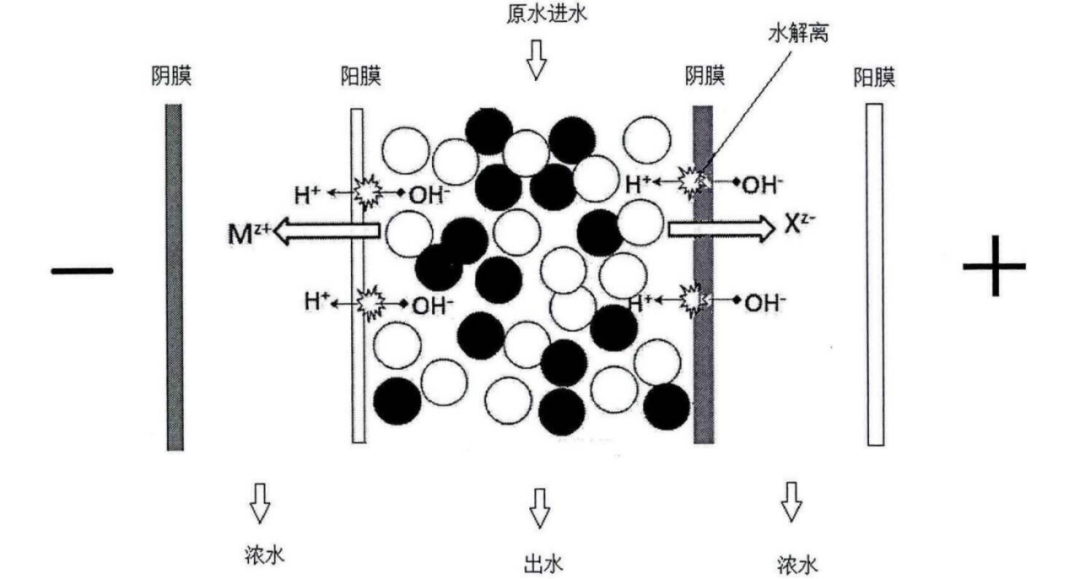

The basic principle of EDI deionization consists of the following three processes:

1. Electrodialysis process

Under the action of applied electric field, the electrolyte in water is selectively migrated through ion exchange resin and discharged with concentrated water, thus removing the ions in water.

2. Ion exchange process

The impurity ions in the water are exchanged by the ion exchange resin, and the impurity ions in the water are combined to achieve the effect of effectively removing the ions in the water.

3, electrochemical regeneration process

The resin was electrochemically regenerated by H+ and OH- produced by the polarization of water at the interface of ion-exchange resin, and the self-regeneration of resin was realized.

02 What are the influencing factors and control methods of EDI?

1, The influence of water inlet conductivity

Under the same operating current, with the increase of raw water conductivity, the removal rate of EDI for weak electrolyte decreased, and the electrical conductivity of effluent increased.

If the raw water conductivity is low, the ion content is also low, and the low concentration of ions makes the electromotive force gradient formed on the surface of the resin and film in the fresh water chamber is also large, resulting in the degree of water dissociation is enhanced, the limit current is increased, and the amount of H+ and OH- generated is large, so that the Yin and cation exchange resin filled in the fresh water chamber has a good regeneration effect.

Therefore, it is necessary to control the inlet water conductivity so that the inlet water conductivity of EDI is less than 40us/cm, which can ensure the qualified outlet water conductivity and the removal of weak electrolytes.

2, The influence of working voltage and current

With the increase of working current, the quality of produced water is continuously improved.

However, if the current is increased after increasing to the highest point, due to the excessive amount of H+ and OH- ions generated by hydro-ionization, in addition to the regeneration resin, a large number of surplus ions act as current-carrying ions to conduct electricity. At the same time, due to the accumulation and blockage of a large number of current-carrying ions during the movement process, and even reverse diffusion, the resulting water quality decreases.

Therefore, the appropriate operating voltage and current must be selected.

3, Influence of turbidity and pollution index (SDI)

The water production channel of EDI module is filled with ion exchange resin, and too high turbidity and pollution index will block the channel, resulting in the increase of system pressure differential and the decrease of water production.

Therefore, proper pretreatment is required, and the RO effluent generally meets the EDI inlet requirements.

4, The impact of hardness

If the residual hardness of the inlet water in EDI is too high, it will lead to scale on the membrane surface of the concentrated water channel, decrease the flow rate of concentrated water, decrease the resistivity of water production, affect the quality of water production, and seriously block the concentrated water and polar water channel of the component, resulting in the destruction of the component due to internal heat.

It can be combined with CO2 removal to soften and add alkali to RO water; When the influent salt content is high, the effect of hardness can be adjusted by adding a primary RO or nanofiltration in combination with salt removal.

5, TOC (total organic carbon) impact

If the content of organic matter in the water is too high, it will cause organic pollution of the resin and the selective permeable film, resulting in an increase in the operating voltage of the system and a decrease in the quality of the produced water. At the same time, it is also easy to form organic colloids in the concentrated water channel and block the channel.

Therefore, when processing, it can be combined with other indicator requirements to add a level of R0 to meet the requirements.

6, The influence of metal ions such as Fe and Mn

Fe, Mn and other metal ions will cause resin "poisoning", and the metal "poisoning" of resin will cause the rapid deterioration of EDI effluent water quality, especially the rapid decline in the removal rate of silicon.

In addition, the oxidation catalysis of variable valence metal on ion exchange resin can cause permanent damage to the resin.

In general, the Fe controlling EDI water intake in operation is less than 0.01mg/L.

7, Influence of C02 in water

HCO3- produced by CO2 in influent water is a weak electrolyte, which easily penetrates the ion exchange resin layer and causes the quality of produced water to decline.

It can be removed by degassing tower before water intake.

8, Influence of total anion content (TEA)

High TEA will reduce the EDI water production resistivity or increase the EDI operating current, while too high running current will lead to increased system current and increase the residual chlorine concentration in polar water, which is unfavorable to the electrode film life.

In addition to the above 8 influencing factors, inlet temperature, pH, SiO2 and oxide also have an impact on EDI system operation.

03 EDI features

In recent years, EDI technology has been widely used in power, chemical, medicine and other industries with high water quality requirements.

Long-term application research in the field of water treatment shows that EDI treatment technology has the following six characteristics:

1, High water quality and stable effluent

EDI technology combines the advantages of electrodialysis continuous desalting and ion exchange deep desalting. Continuous scientific research and practice show that the use of EDI technology for desalting again can effectively remove ions in water, and the effluent purity is high.

2, low equipment installation conditions, small footprint

Compared with the ion exchange bed, EDI device is small in size, light in weight, and does not need to set up acid and alkali storage tanks, which can effectively save space.

Not only that, the EDI device is a complete structure, the construction period is short, and the field installation workload is small.

3, simple design, easy operation and maintenance

EDI processing device can be modular production, automatic continuous regeneration, do not need large, complex regeneration equipment, put into operation, easy to operate and maintain.

4, water purification process automatic control is simple

EDI device can connect multiple modules to the system in parallel, the module operation is safe and stable, the quality is reliable, so that the operation and management of the system are easy to realize program control, and the operation is convenient.

5, no waste acid waste lye discharge, conducive to environmental protection

EDI device does not require acid, alkali chemical regeneration, basically no chemical waste discharge.

6, high water recovery rate, EDI treatment technology water utilization rate is generally as high as 90%

In summary, EDI technology has great advantages in water quality, operation stability, operation and maintenance difficulty, safety and environmental protection.

However, it also has some shortcomings, EDI device has higher requirements for inlet water quality, and its one-time investment (infrastructure and equipment costs) is high.

It should be noted in particular that although the cost of EDI infrastructure and equipment is slightly higher than that of the mixed-bed process, EDI technology still has certain advantages after considering the cost of device operation.

For example, a pure water station compared the investment and operating costs of the two processes, and the EDI device can offset the investment difference with the mixed bed process after one year of normal operation.

04 Reverse osmosis +EDI VS traditional ion exchange

1, Initial investment comparison of the project

In terms of the initial investment of the project, in the water treatment system with small water production flow, the huge regeneration system required by the traditional ion exchange process is cancelled due to the reverse osmosis +EDI process, especially the cancellation of two acid storage tanks and alkali storage tanks, which not only greatly reduces the equipment procurement cost, but also saves about 10% to 20% of the land area. Thus, the cost of civil construction and land expropriation for plant construction is reduced.

Since the height of the traditional ion exchange equipment is generally above 5m, and the height of the reverse osmosis and EDI equipment is within 2.5m, the height of the water treatment workshop can be reduced by 2 ~ 3m, thereby saving 10% ~ 20% of the plant civil construction investment.

Considering the recovery rate of reverse osmosis and EDI, all the concentrated water of the secondary reverse osmosis and EDI are recovered, but the concentrated water of the primary reverse osmosis (about 25%) needs to be discharged, and the output of the pretreatment system needs to be increased accordingly. When the traditional coagulation and clarifier filtration process is used in the pretreatment system, the initial investment needs to be increased by about 20% compared with the pretreatment system of the ion exchange process.

Overall, the initial investment of the reverse osmosis +EDI process in a small water treatment system is roughly equivalent to that of the traditional ion exchange process.

2, Comparison of operating costs

As we all know, in terms of pharmaceutical consumption, the operating cost of reverse osmosis processes (including reverse osmosis dosing, chemical cleaning, wastewater treatment, etc.) is lower than that of traditional ion exchange processes (including ion exchange resin regeneration, wastewater treatment, etc.).

However, in terms of power consumption and spare parts replacement, the reverse osmosis plus EDI process is much higher than the traditional ion exchange process.

According to statistics, the operating cost of the reverse osmosis plus EDI process is slightly higher than that of the traditional ion exchange process.

Overall, the overall operation and maintenance cost of reverse osmosis plus EDI process is 50% ~ 70% higher than that of traditional ion exchange process.

3, Reverse osmosis +EDI strong adaptability, high degree of automation, little environmental pollution

The reverse osmosis + EDI process has strong adaptability to the salt content of raw water. The reverse osmosis process can be used from seawater, brackish water, mine drainage water, groundwater to river water, while the ion exchange process is uneconomical when the dissolved solid content of the inlet water is greater than 500 mg/L.

Reverse osmosis and EDI do not require acid and base regeneration, do not require a large amount of acid and base consumption, nor do they produce a large amount of acid and base wastewater, only a small amount of acid, base, scale inhibitor and reducing agent dosing can be done.

In terms of operation and maintenance, reverse osmosis and EDI also have the advantages of high automation and easy program control.

4, reverse osmosis +EDI equipment high cost, difficult to repair, concentrated salt water treatment is difficult

Although the reverse osmosis and EDI process has many advantages, when the equipment fails, especially when the reverse osmosis membrane and EDI membrane stack are damaged, it can only be replaced by outage, and in most cases, professional and technical personnel are required to replace it, and the outage time may be longer.

Although reverse osmosis does not produce a large amount of acid and alkali wastewater, the recovery rate of primary reverse osmosis is generally only 75%, which will produce a large amount of concentrated water, and the salt content of concentrated water will be much higher than that of raw water, and this part of concentrated water has no mature treatment measures at present, and will pollute the environment once discharged.

At present, in domestic power plants, most of the reverse osmosis brine is recycled for coal washing and ash humidification. Some universities are conducting research on the process of evaporation, crystallization and purification of concentrated brine, but it is costly and difficult, and has not been widely used in industry.

The cost of reverse osmosis and EDI equipment is relatively high, but in some cases even lower than the initial engineering investment of traditional ion exchange processes.

In large water treatment systems (when the system produces a large amount of water), the initial investment of reverse osmosis and EDI systems is much higher than that of traditional ion exchange processes.

In a small water treatment system, the reverse osmosis plus EDI process in a small water treatment system and the traditional ion exchange process in terms of initial investment is about the same.

In summary, when the output of the water treatment system is small, priority can be given to the use of reverse osmosis plus EDI treatment process, which has low initial investment, high degree of automation and little environmental pollution.